11 Nov Science of Synthetics: Metalube® Uses Synthetic Technology to Deliver Next Generation in Wire Drawing Lubrication

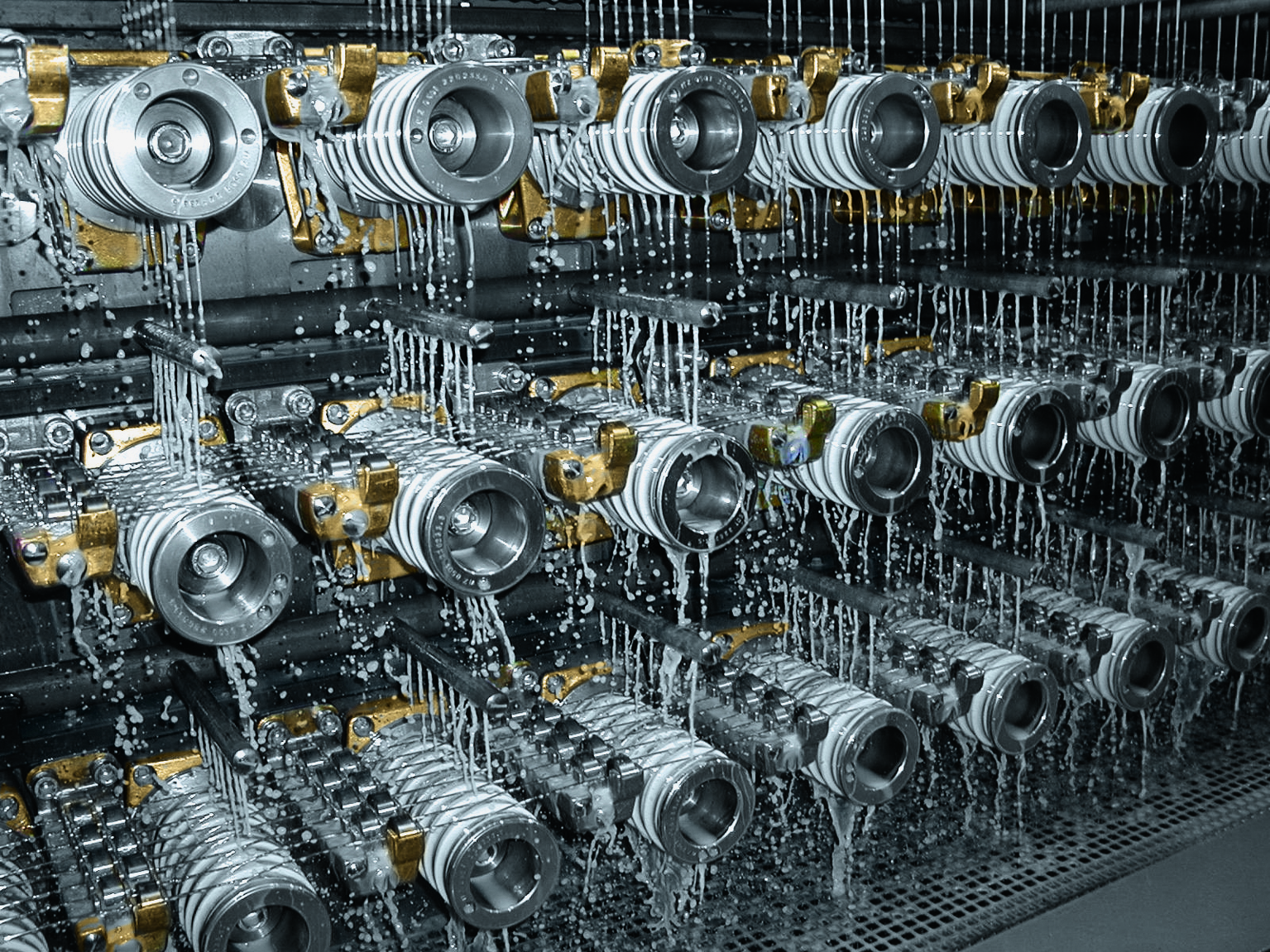

Metalube® is utilising scientific advancements in synthetic technology to deliver advanced lubrication solutions to the wire drawing industry. With the advancement of wire machinery and the expansion of production capability, Metalube has formulated an advanced range of synthetic lubricants specially developed to address the high-performance objectives of today’s multiwire machines.

Already approved and in use in the latest high-performance machines, Metalube’s synthetic Lubricool and Metarol products are delivering better performance, increased stability, and improved cleanliness over mineral oil-based products.

What makes a synthetic lubricant a better option?

Synthetic lubricants are highly stable fluids used in fine wire drawing processing applications where high levels of lubrication and cleanliness are needed to cope with the high speeds of modern machinery. Proven to reduce wire break frequency by 50%, synthetic lubricants deliver increased efficiency for wire drawing machinery.

Whether it’s poor temperature control, unreliable filtration, a small system or highly pressurised pumps, these factors all shorten the product life of the typical mineral oil-based lubricant. Synthetic fluids, however, are much less reactive lubricants and so can run much cleaner at lower concentrations. Additionally, they are better at rejecting contamination – a soluble oil will naturally try to emulsify into the fluid. The result being:

- Improved cleanliness

- Increased efficiency

- Better lubricant stability

- More consistency in operation

- Improved component life

Chris Nettleship, Technical Director at Metalube explains why synthetic lubricants are more stable: “Mineral oils are prone to changes in particle size which can lead to instability as the lubricant interacts with ions in reactive copper and hard water salts. The result for the manufacturer is an upset in the overall balance of the fluid leading to poor detergency, shortened fluid life and the need to add additional cleaning products. Synthetic fluids are less reactive lubricants and so run cleaner for longer, at lower concentrations, eliminating the need for additive products.

Let’s stay in touch

Contact us today to discuss your lubrication needs.