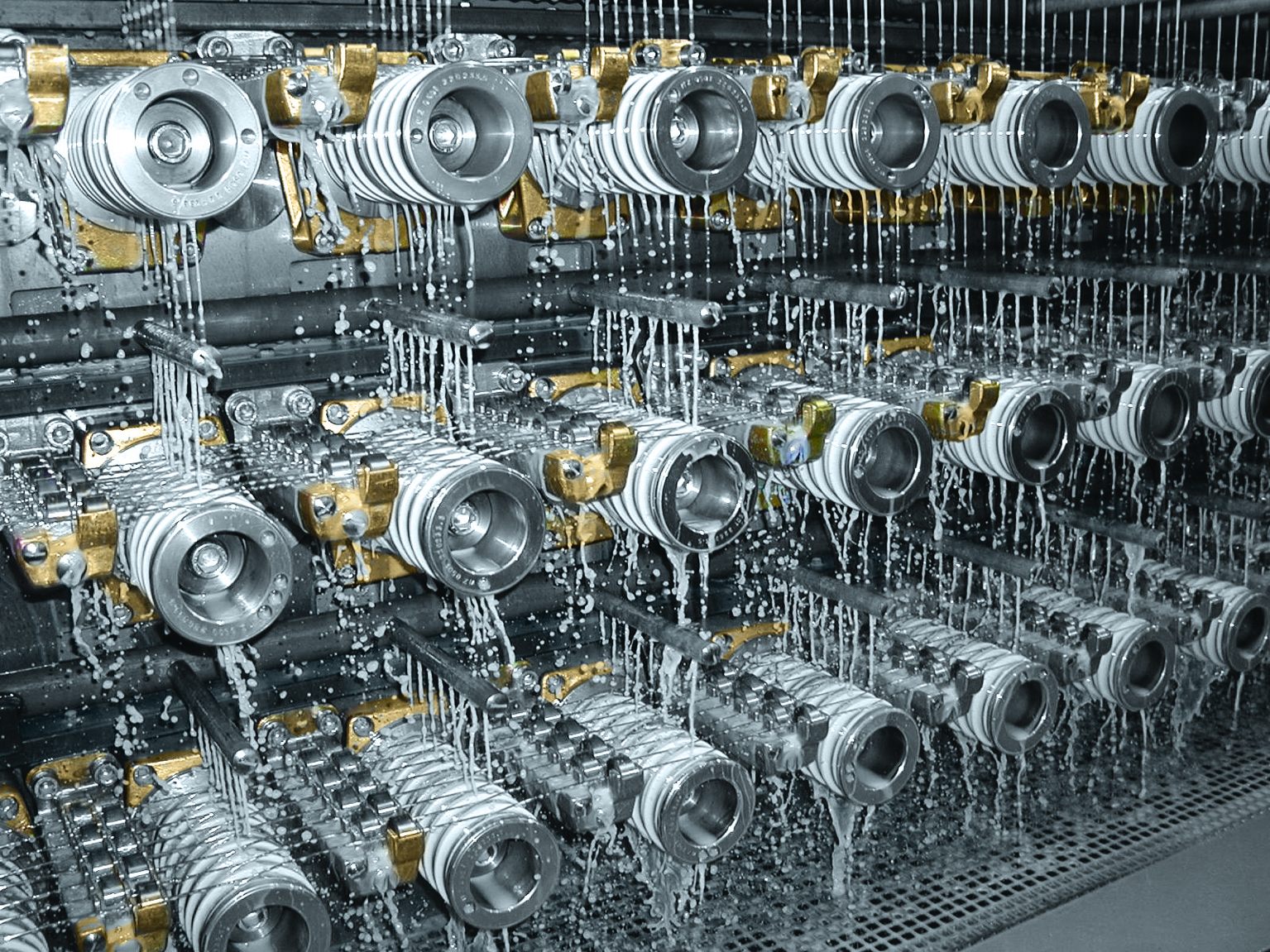

A manufacturer of galvanised steel sections was using an off-the-shelf, semi-synthetic metal working fluid at 10% to lubricate their rollforming process. The operators were having to manually drying the sections after forming. Despite the drying they were still getting white rust when the sections were stacked. The emulsion was changed monthly. Cool-Tek™ 250 was recommended at 5%. Initial tests showed a high level of corrosion protection after rolling and a good level of lubrication.

Cool-Tek™ 250

Outcome

5% Cool-Tek™ 250 was trialled on a mill with a 100L emulsion tank. The line was rolling 3-5mm diameter galvanised strip (DX51) into simple angles. The stacked sections showed no white rust on either exposed or sandwiched surfaces. Because of this the operators found they no longer needed to dry the sections after forming, greatly improving line efficiency. The emulsion sump life was extended to greater than 2 months, further improving efficiency and reducing consumption.

In addition to the improved corrosion protection it was also observed that the mill was much cleaner due to the superior fines handling and detergency. Cool-Tek™ 250 was adopted as the main lubricant across the site (15 roll-forming lines)

Summary

Cool-Tek™ 250 at 5% was found to give good lubrication for the roll-forming process and greatly improved; quality (through superior corrosion protection and cleanliness), efficiency (by removing the need for drying) and cost effectiveness (through extended sump life and lower in-use concentration).

Enquire now to speak to an expert

Please submit the below contact form to get in touch with an expert